Theoretical Analysis and CAE Simulation

We have expertise in in-depth theoretical analysis to evaluate the casting quality of products in advance. We are able to provide detailed casting simulation analyses using leading Computer-Aided Engineering (CAE) software in the industry, including MAGMA, ADSTEFAN, CAST-DESIGNER, and ANSYS. These CAE simulations help accurately predict casting behavior and significantly reduce the number of mold trial iterations.

If customers encounter casting quality issues such as porosity, misruns, or cracking, we can analyze the results using CAE software and identify the root causes. Based on these analyses, we provide precise and effective guidance to help customers improve casting quality, as illustrated below.

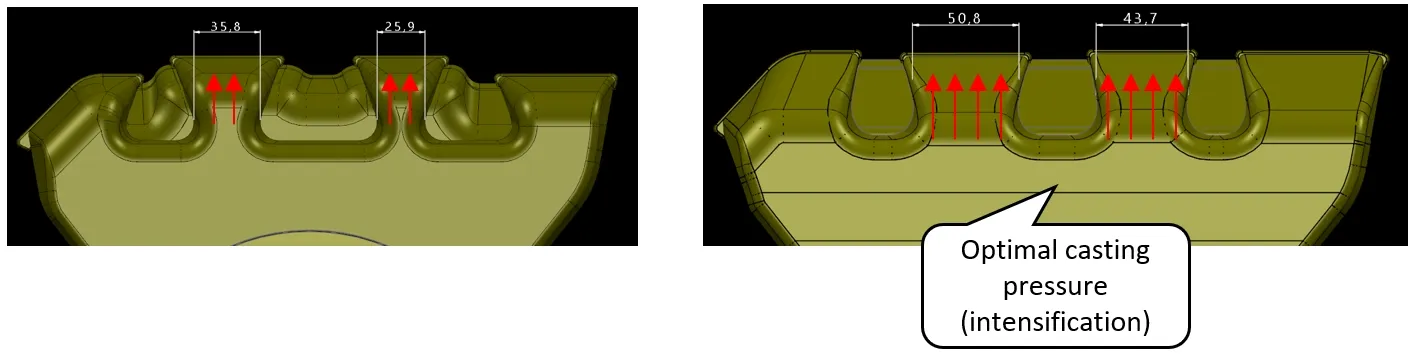

Examples of Quality Improvements Before Mold Production Begins.

Before CAE

After CAE

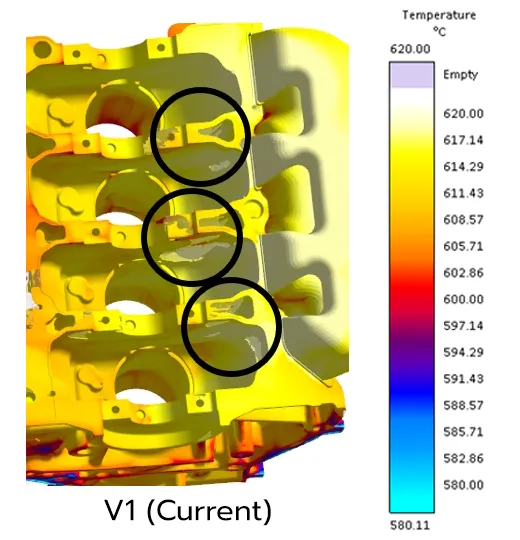

Filling Temperature analysis shows that the temperature distribution during mold filling is not optimal in certain areas inside the mold. Some regions are either too cold or excessively hot. These issues can be resolved by modifying the mold design and adjusting the process parameters.

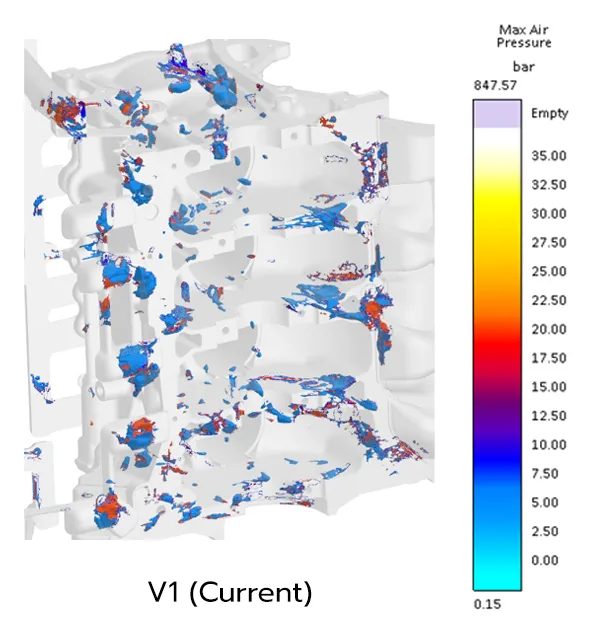

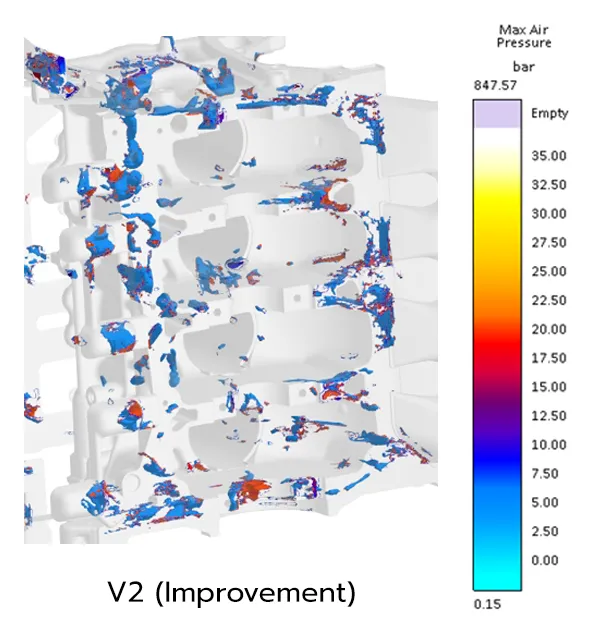

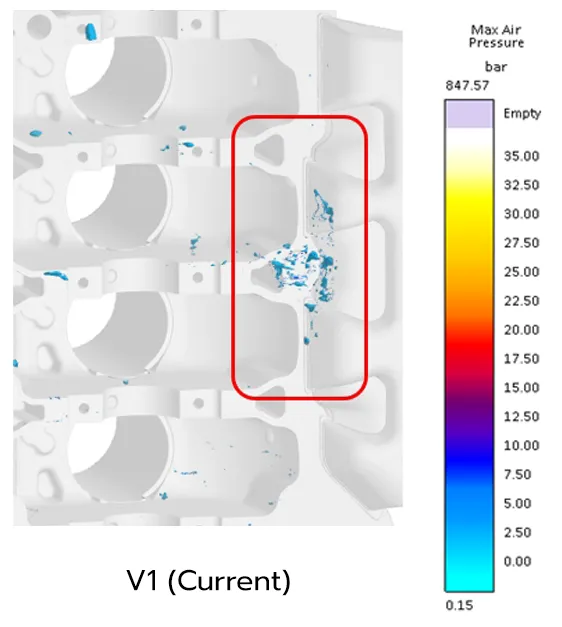

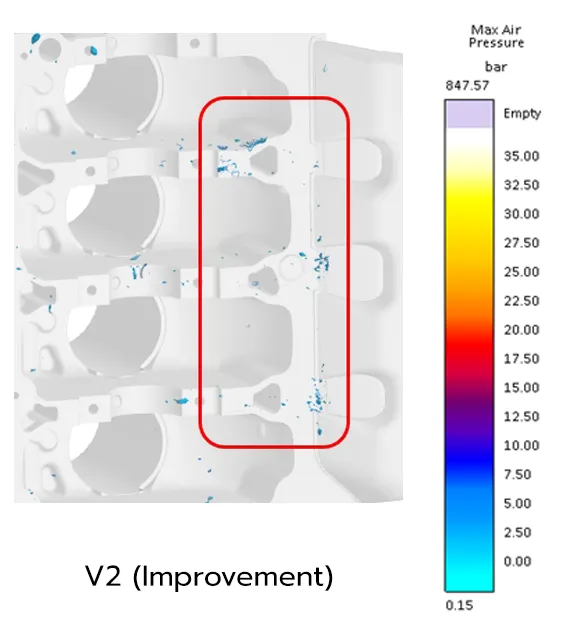

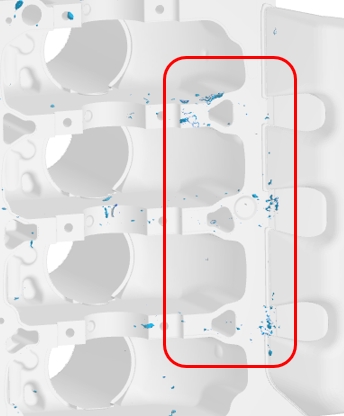

Max Air Pressure

Max Air Pressure analysis enables engineers to improve the design of the runner system, gates, and the placement of air vents in order to reduce or eliminate this issue, which is one of the primary causes of poor casting quality.

Before CAE

After CAE

Entrapped AIR

Simulation of molten metal flow into the mold helps identify locations where air is trapped or areas where the metal does not completely fill the cavity, allowing mold design improvements to be made before actual production

Before CAE

After CAE

Analysis for Improvement

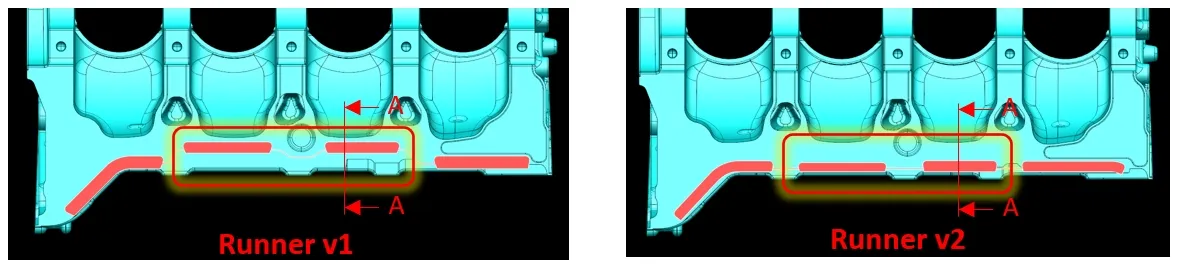

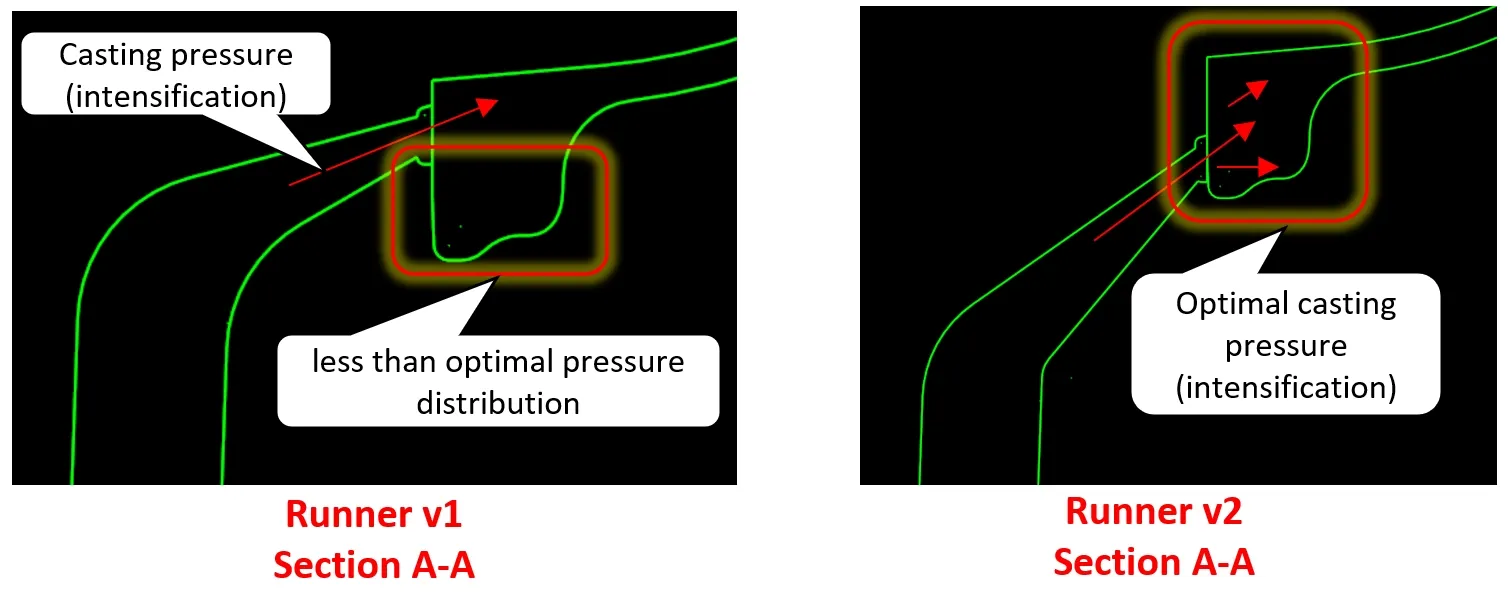

Optimized Air-Trap System V2 (Enhanced Design) Why does the V2 runner design improve air flow and evacuation efficiency?

1. Gate Position

2. Gate angle

3. Width of runner