OUR SERVICES

Meiwa Mold (Thailand) Co., Ltd.

We provide comprehensive mold services, from design, manufacturing, and assembly to quality inspection and engineering analysis, using advanced technology and expertise to meet all customer needs.

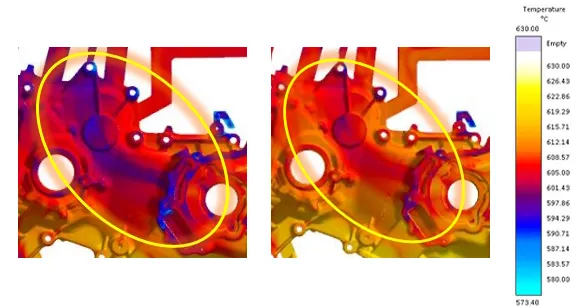

Computer-Aided Engineering (CAE)

We have expertise in in-depth theoretical analysis to evaluate casting quality in advance. We provide detailed casting simulations using leading CAE software, including MAGMA, ADSTEFAN, CAST-DESIGNER, and ANSYS. These simulations accurately predict casting behavior and reduce mold trial iterations.

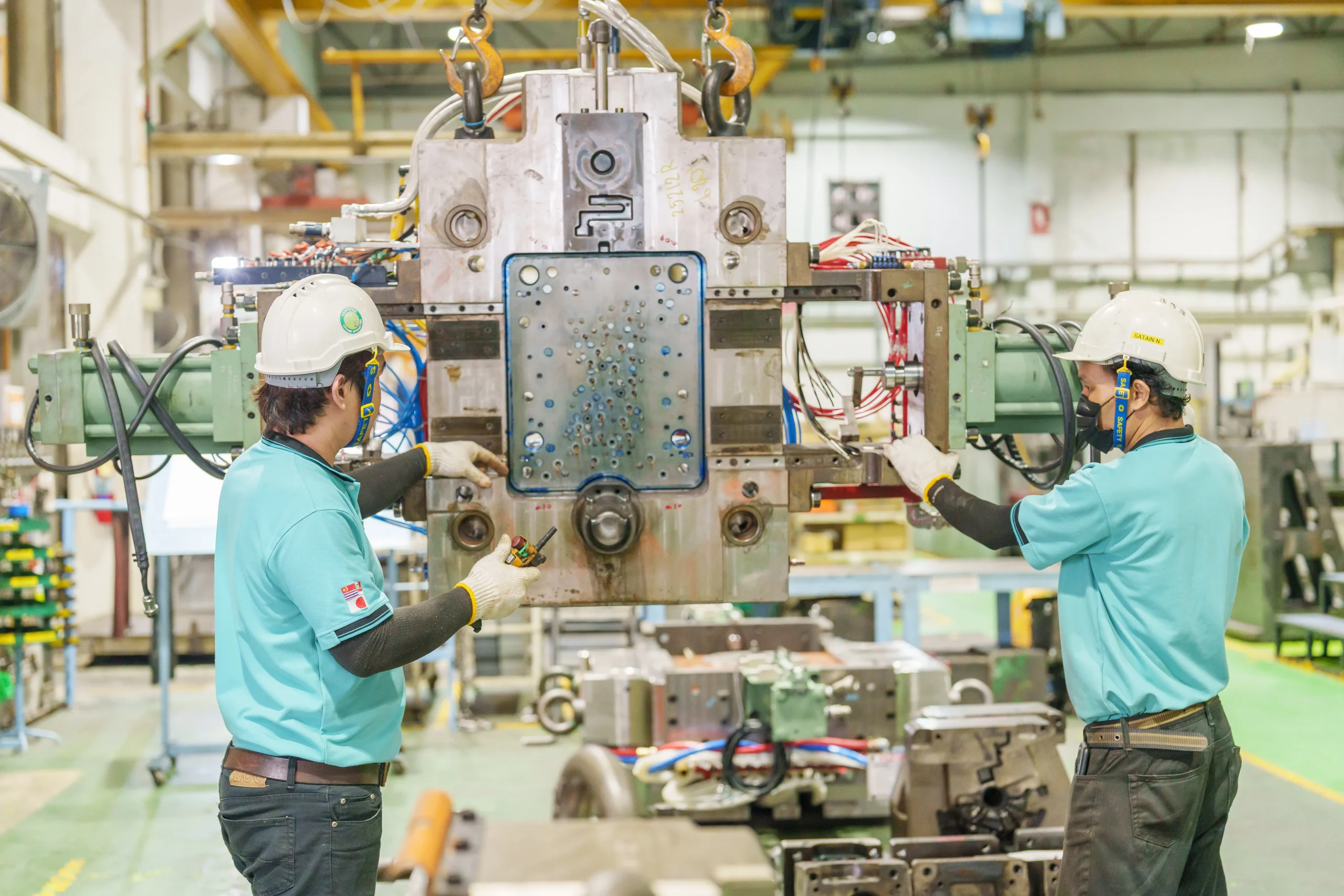

Mold assembly

Our assembly process is paperless, using tablets for drawings and models. A custom-developed application manages feedback, photographs, and checklists, ensuring high quality for completed molds. We also use a flow cooling checker to adjust water temperature, along with a thermoscanner to monitor mold temperature.

Mold manufacturing process

We have state-of-the-art machinery to support high-precision mold production and the latest tooling technologies, such as carbide drills, to improve efficiency and speed up processing. We also utilize high-speed and 5-axis machines to reduce production time. In addition, we design custom jigs for workpiece setup within the machines, ensuring accurate and time-saving operations. The result is superior quality, faster machining, and minimal setup time.

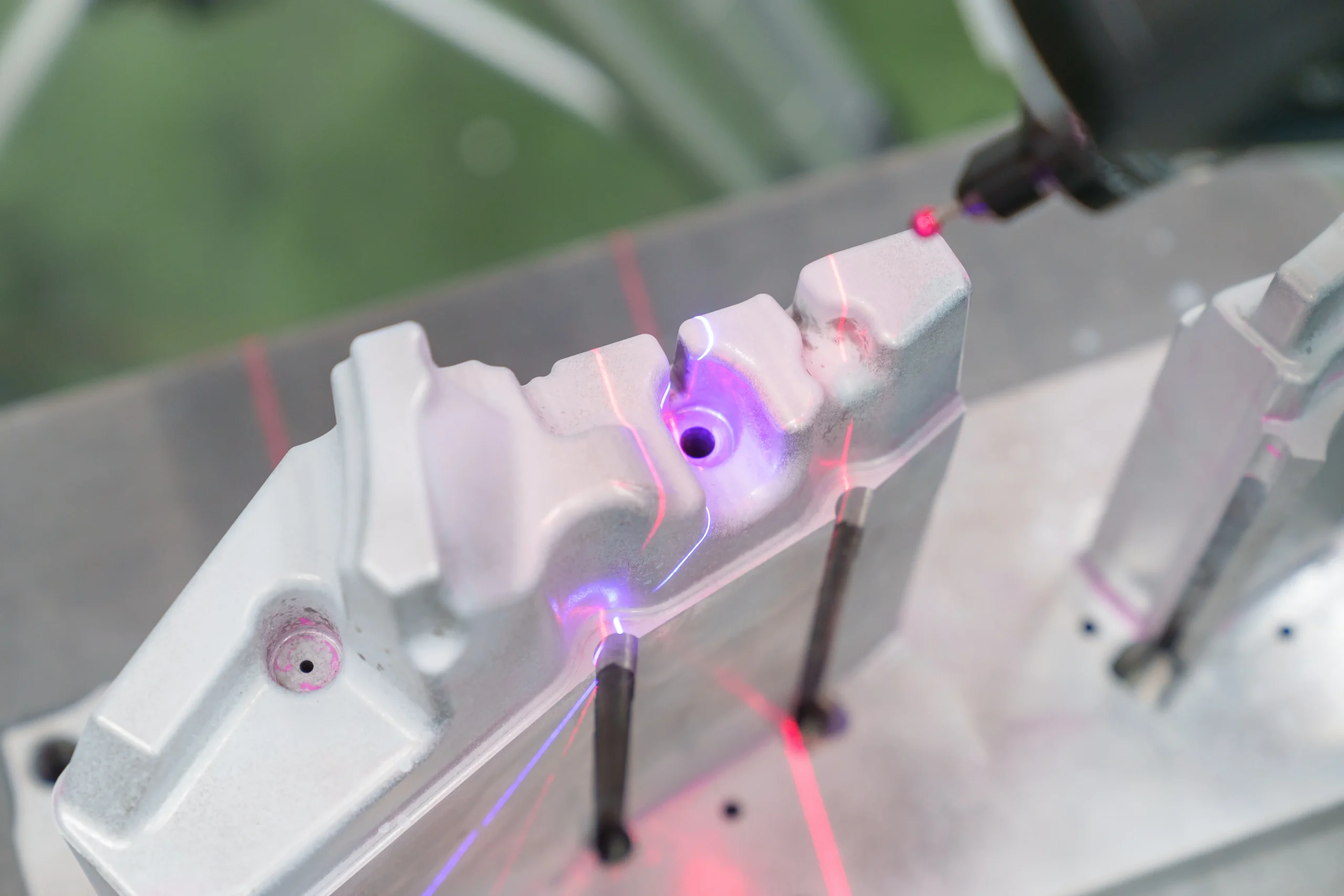

Quality Assurance (QA,QC)

Mold Quality Assurance We use automated measurement processes with a Coordinate Measuring Machine (CMM). Complex shapes are also verified using a laser scanner (SCAN), ensuring accurate and reliable results.

Aluminum Part Warranty Inspection We inspect molded parts to ensure accuracy and customer satisfaction.

OUR PRODUCTS

Our Products: Molds, Parts, and Repair

We specialize in manufacturing and developing high-quality molds, precision spare parts, and comprehensive mold maintenance services, using advanced technology and a team of professional engineers.

From design, fabrication, and production to quality inspection, we can meet customer needs across various industries, including automotive, electronics, and more.

Contact Us

Mold and Parts Products

We manufacture molds of all sizes, from small to large, for both domestic and international customers, and provide comprehensive after-sales services and lifetime support. Our mold production capacity ranges from 25T to 1650T, and up to 2250T for core and cavity components only.

In addition, we supply both standard parts and custom-made components, along with technical consultation and professional after-sales service.

SIZE Less than 350T

- COCK BODY

- FAN BOSS

- NOZZLE HOLDER

- CYLINDER HEAD FRONT

- PISTON CLUTCH

- Etc.

SIZE 500-800T

- STATOR WHEEL

- BODY OIL PUMP

- COVER WATER PUMP

- BODY WATER PUMP

- ADAPTER

- CAM HOUSING

- OIL PAN

- VALVE BODY

- HOUSING EXTENSION

- COVER FRONT

- NOZE ELEBLOW

- FRONT WHEEL

- REAR WHEEL

- Etc.

SIZE 1000-1650T

- TIMING CHAIN COVER

- CASE TRANSAXEL

- HOUSING TRANSAXEL

- CRANK CASE

- CASE TRANSFER

- FRONT WHEEL

- REAR WHEEL

- Etc.

Size 2250T Core Cav.

- CASE TRANSMISSTION

- CYLINDER BLOCK

- Etc.

Repair & Maintenance

We provide comprehensive mold planning and maintenance services to ensure efficient operation and maximize mold lifespan. We prioritize root cause analysis to identify underlying issues and implement long-term maintenance plans that minimize maintenance frequency.

After sale service : Support Tryout

We can be a leading, experienced and reliable diecast company that can support mold trials for customers.