Technology and Know-how

Specialized Technology and Expertise

Enhancing Mold Manufacturing Efficiency

Meiwa Mold (Thailand) Co., Ltd. continuously develops innovations to increase productivity, extend mold lifespan, and reduce production issues through specialized solutions and equipment designed specifically for the die casting mold industry.

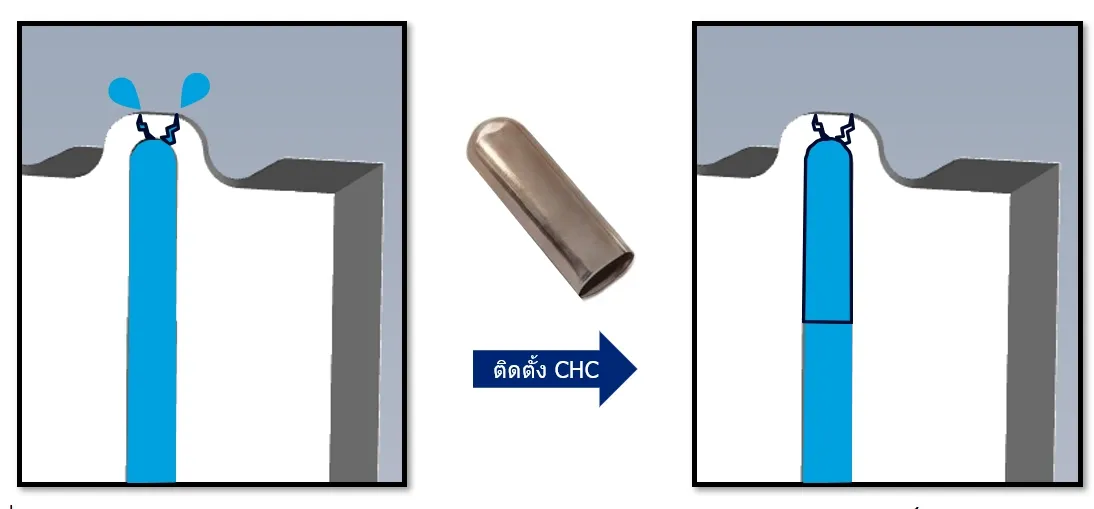

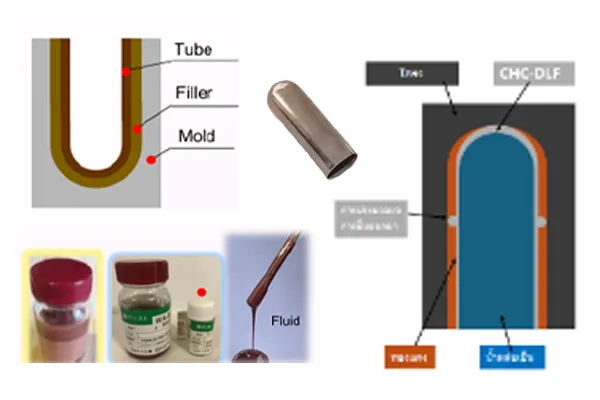

CHC Product Line for Cooling Systems and Leak Prevention

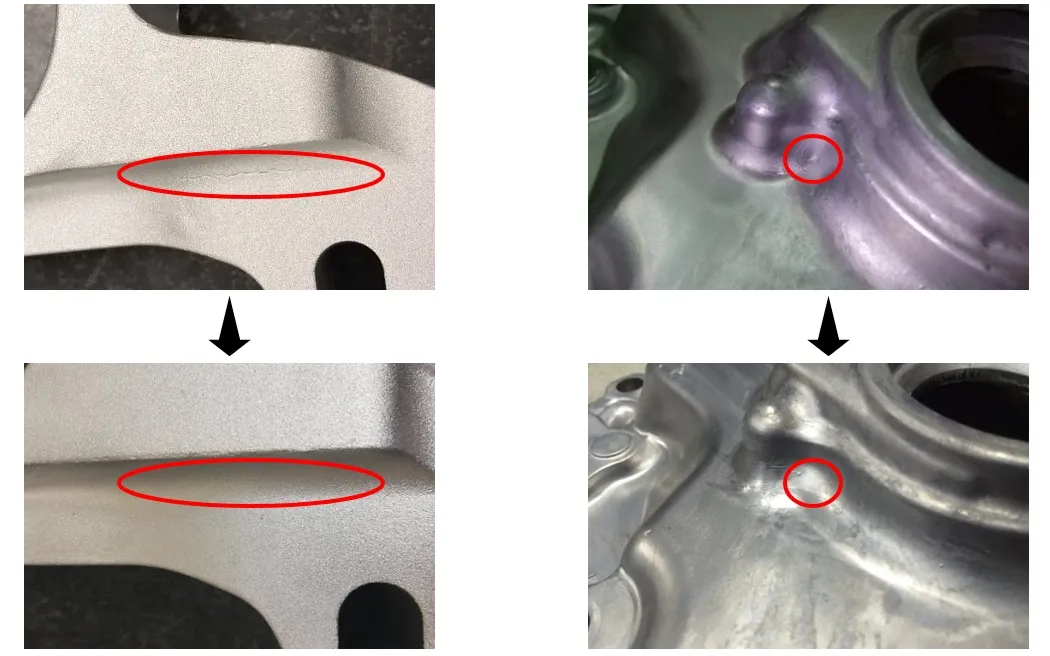

Status water leak problem cause no CHC.

Status no problem of water leak after CHC installed.

CHC Std. (Cooling Half Cap) and CHC Long

CHC – Half-cap internal cooling cover to increase your casting mold production efficiency. We have developed a stainless steel cover that strengthens the internal cooling system by inserting into the cooling holes.

Spec. Cooling Half Cap is as follows:

| Type | Size (mm) | Thickness (mm) | Length (mm) | Material |

|---|---|---|---|---|

| CHC 3 Std. | Φ3 | 0.15 | 25 | SUS316 |

| CHC 4 Std. | Φ4 | 0.15 | 30 | SUS316 |

| CHC 6 Std. | Φ6 | 0.30 | 30 | SUS316 |

| CHC 8 Std. | Φ8 | 0.30 | 40 | SUS316 |

| CHC 11 Std. | Φ11 | 0.40 | 40 | SUS316 |

| CHC 14 Std. | Φ14 | 0.48 | 40 | SUS316 |

| CHC 6 Long. | Φ6 | 0.30 | 110 | SUS316 |

| CHC 8 Long. | Φ8 | 0.30 | 110 | SUS316 |

| CHC 11 Long. | Φ11 | 0.30 | 110 | SUS316 |

Feature:

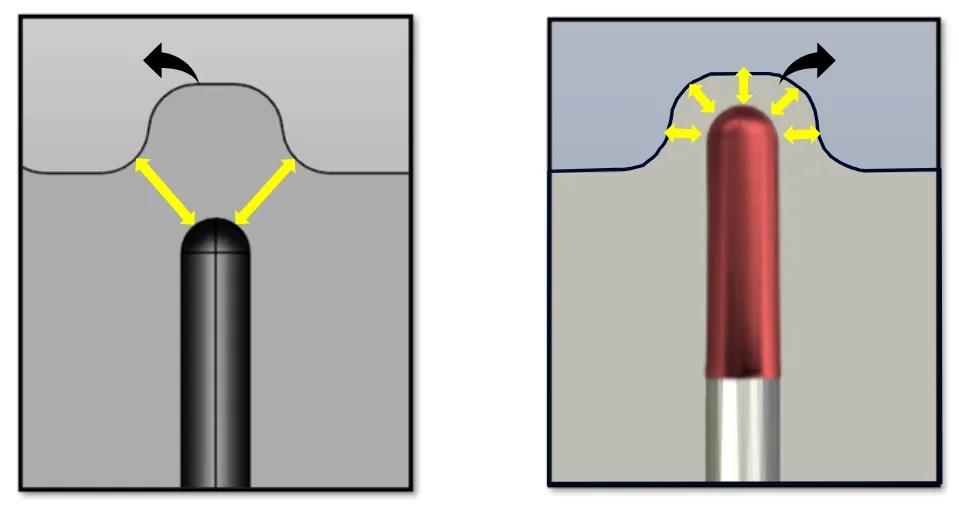

- Prevent water leakage and cracks in cooling holes in casting molds.

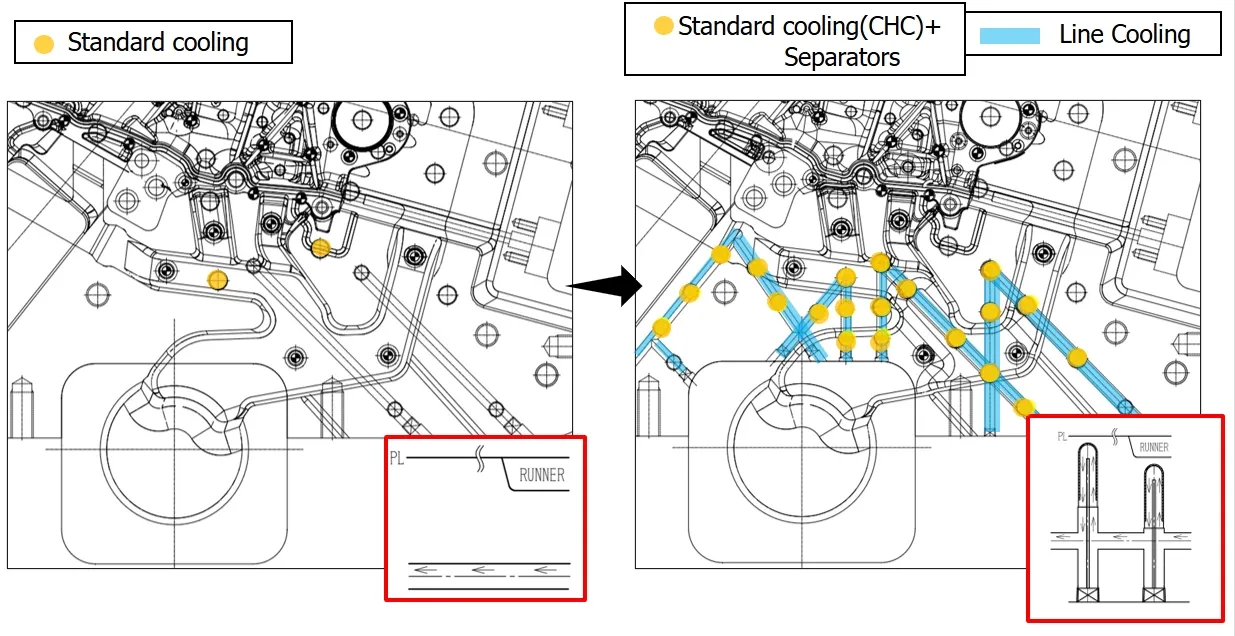

- It enables more efficient cooling system design compared to standard cooling system designs.

- Prevent rust at the cooling holes.

- Improves the quality and productivity of castings.

- Reduces cycle time by adding cooling lines at high-heat areas of the die, such as the gate face, lowering die temperature by over 60 °C and shortening spray cooling time by 5 seconds.

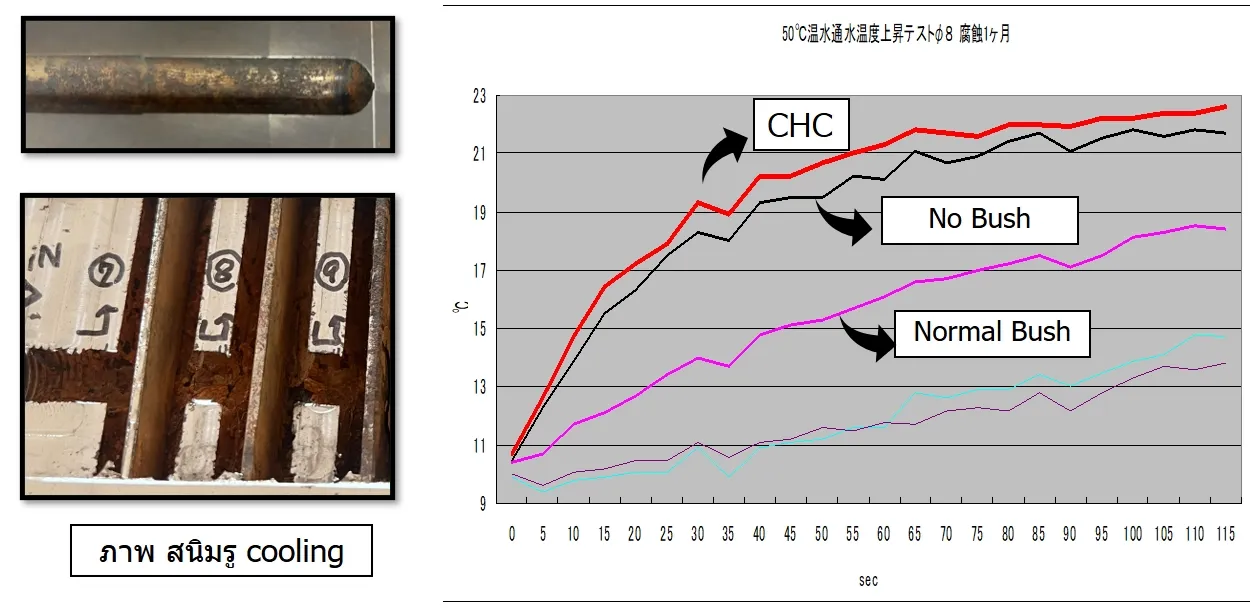

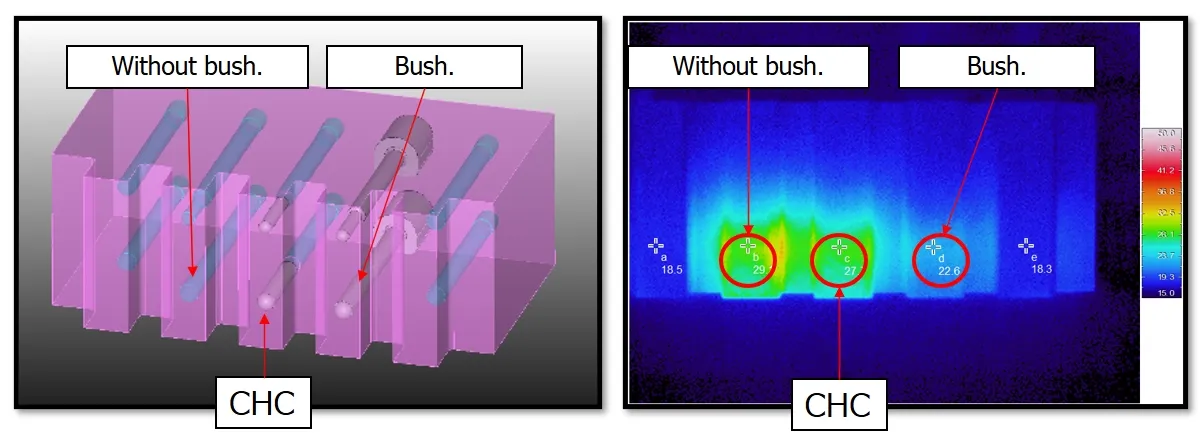

- Comparing holes equipped with CHC to those with regular bushings, a temperature difference of over 5 °C is observed. The induction properties are similar to holes without any bushings installed. When comparing the use of CHC to holes without bushings, the cooling performance is similar, whereas holes with regular bushings show lower cooling efficiency.

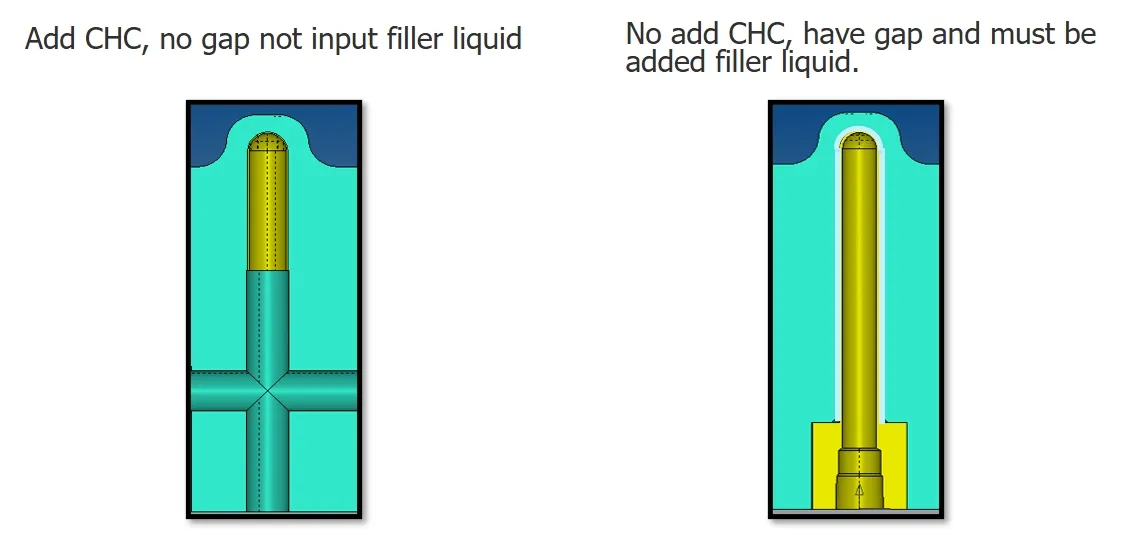

- It is not necessary to add filler according to the maintenance schedule, and even during rework, such as nitrocarburizing, disassembly of the parts is not required (verified by treatment at 550 °C).

- It is not necessary to add filler according to the maintenance schedule, and even for repair work, such as surface plating, it is not necessary to remove the CHC.

- Testing conducted by baking at 550 °C confirmed that the CHC remains securely in place.

CHC STEP

It is developed from CHC Std. and is used for cooling with 2 sizes in the same hole, which can be produced according to the depth of the actual cooling hole.

Feature:

- Prevents water leakage and cracks in cooling holes in casting molds.

- Improves casting quality and productivity.

- Enables more efficient cooling system design compared to standard cooling systems.

- Prevents rust at cooling holes.

- Reduces cycle time by adding cooling lines to high-temperature die areas, such as the gate face. This reduces die temperature by more than 60 °C and

Cooling Half Cap Diameter Length Free (CHC-DLF)

The cap is made of stainless steel tube, allowing for a high degree of design freedom in the diameter and length of the cover. The space between the cavity and the CHC-DLF is filled with copper, and the copper is cooled after fabrication to seal the CHC-DLF in place. The same high-precision cooling holes as the CHC are not required, and it can be mounted on medium-sized molds without modifying the surrounding parts.

Feature:

- Similar to CHC but with fewer cutting limitations than CHC Std.

Meiwa cooling pipe ( M-Cool)

M Cool is a mold cooling system developed by Meiwa Group to increase productivity and extend mold life.

Features:

- Short delivery time / low cost.

- Compact size – approximately 1.3 times the drainage rate compared to the standard model.

- No need to change the mold design when replacing with another brand.

- Only the inner tube can be replaced for maintenance.

M-Cool Specifications: Two Types – O-RING (MCM) and M6 Threaded (MCR)

MCM

MCR

Head Section – Material: Brass

Inner Pipe

| Size (mm) | Material | OD (mm) | ID (mm) | Length (mm) |

|---|---|---|---|---|

| 1.2 | SUS304 | Φ 1.26 | Φ 0.90 | 620 |

| 1.4 | SUS304 | Φ 1.48 | Φ 1.12 | 620 |

| 1.8 | SUS304 | Φ 1.81 | Φ 1.45 | 620 |

| 2.1 | SUS304 | Φ 2.11 | Φ 1.69 | 620 |

Outer Pipe

| Material | OD (mm) | ID (mm) | Length (mm) |

|---|---|---|---|

| SUS304 | Φ 6 | Φ 3 | 100–600 |

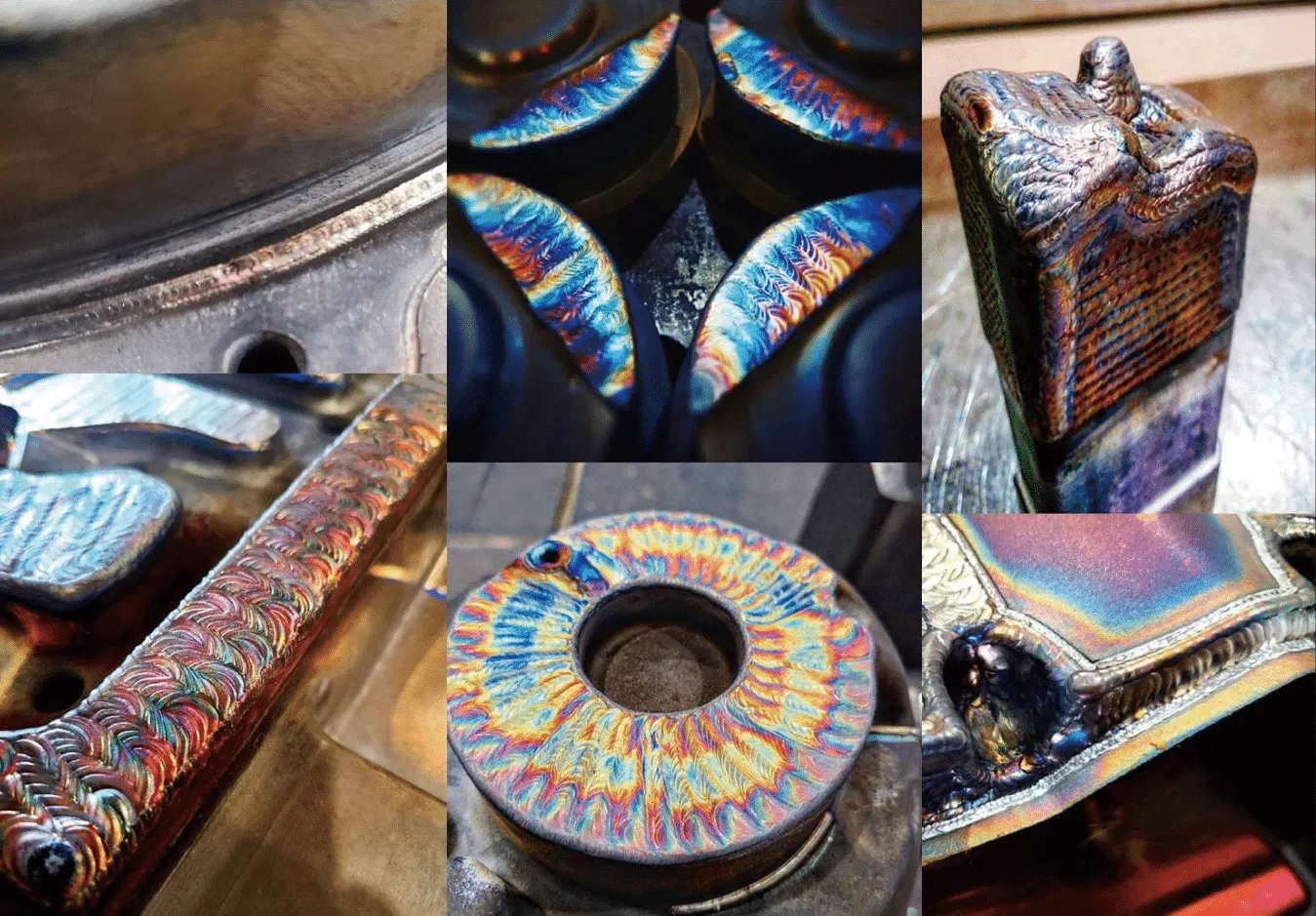

ALW welding wire

High-Temperature Molten Aluminum Die Casting Using TIG/Laser Welding.

Application Features:

- Excellent heat and wear resistance

The welding material offers outstanding resistance to high temperatures and abrasion, and is highly effective in preventing erosion and adhesion caused by molten metal. - Prevention of molten metal adhesion and premature wear

The process prevents molten metal from bonding or fusing to the surface, which helps reduce rapid wear at the aluminum melt inlet area. - Welding is performed using Meiwa Group’s specialized welding technique, rather than conventional welding methods.

Applications:

- Deposition for low-pressure die casting molds and dies.

- Deposition to address erosion, adhesion, and similar issues in large-scale injection molding machines exceeding 4,000 tons (Mega) and 6,000 tons (Giga).